Circular barrier plastic packaging

Most plastic packaging with barrier functionality is not currently recyclable, which presents a significant challenge to achieving a circular economy. IonKraft addresses this issue with IONX, a plasma-based coating technology that delivers performance comparable to that of traditional multilayer structures or fluorinated barriers, while preserving full recyclability.

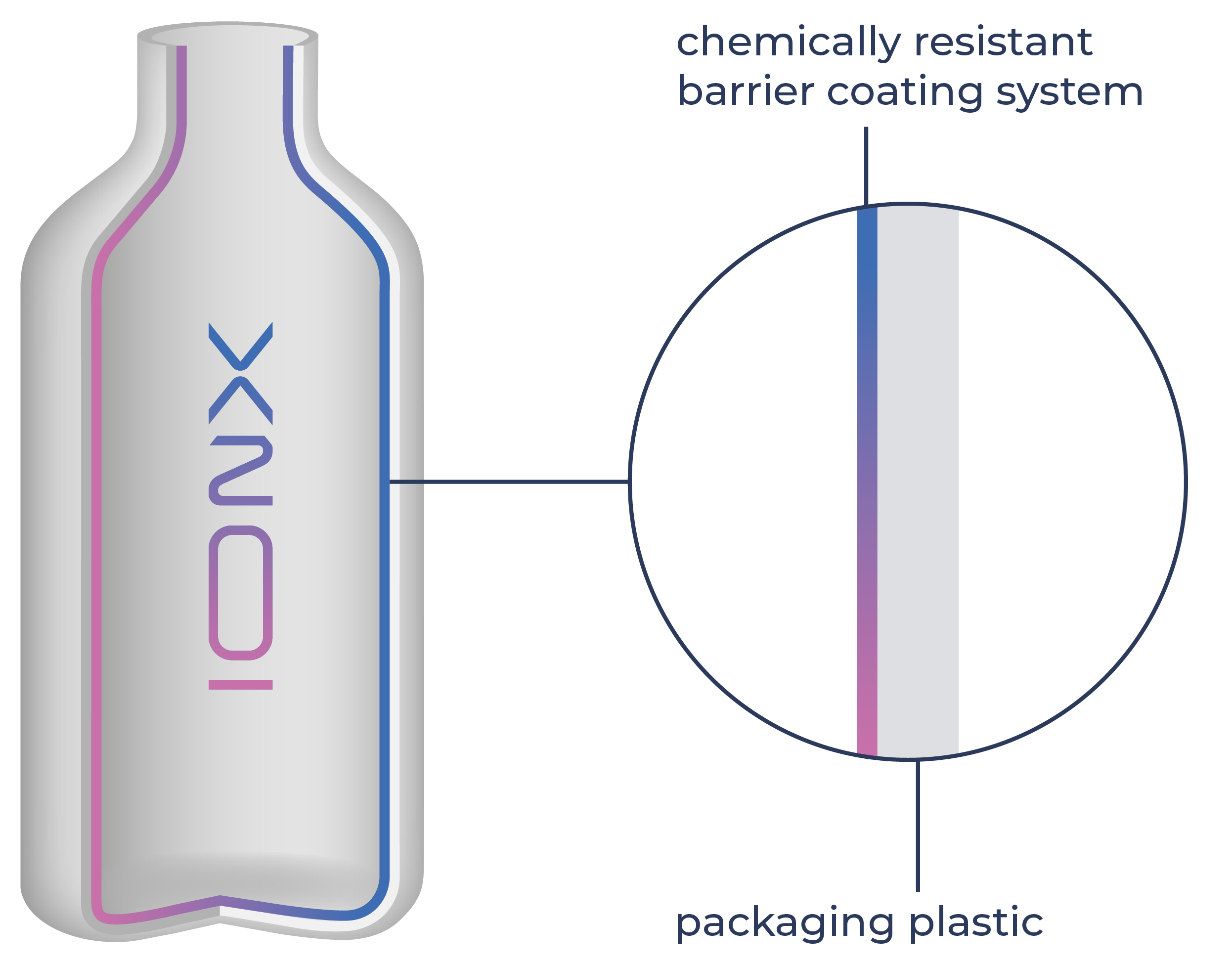

IONX utilizes a refined plasma-enhanced chemical vapor deposition (PECVD) process to apply an ultra-thin, glass-like barrier layer to the inside of plastic containers. This nanocoating reliably prevents substance migration, enabling the use of mono-material packaging solutions.

IONX is fully proven for various applications and launched to the market. The recyclability has been validated by Recyclass.

The coating process is fully automated, scalable, and can be seamlessly integrated into existing manufacturing lines. This facilitates the development of plastic packaging that combines high performance with genuine recyclability and a low carbon footprint.

Our coating technology

• Gas barrier equal to multilayer with EVOH

• Solvent barrier equal to fluorination

• 100% recyclable

Applications and use cases

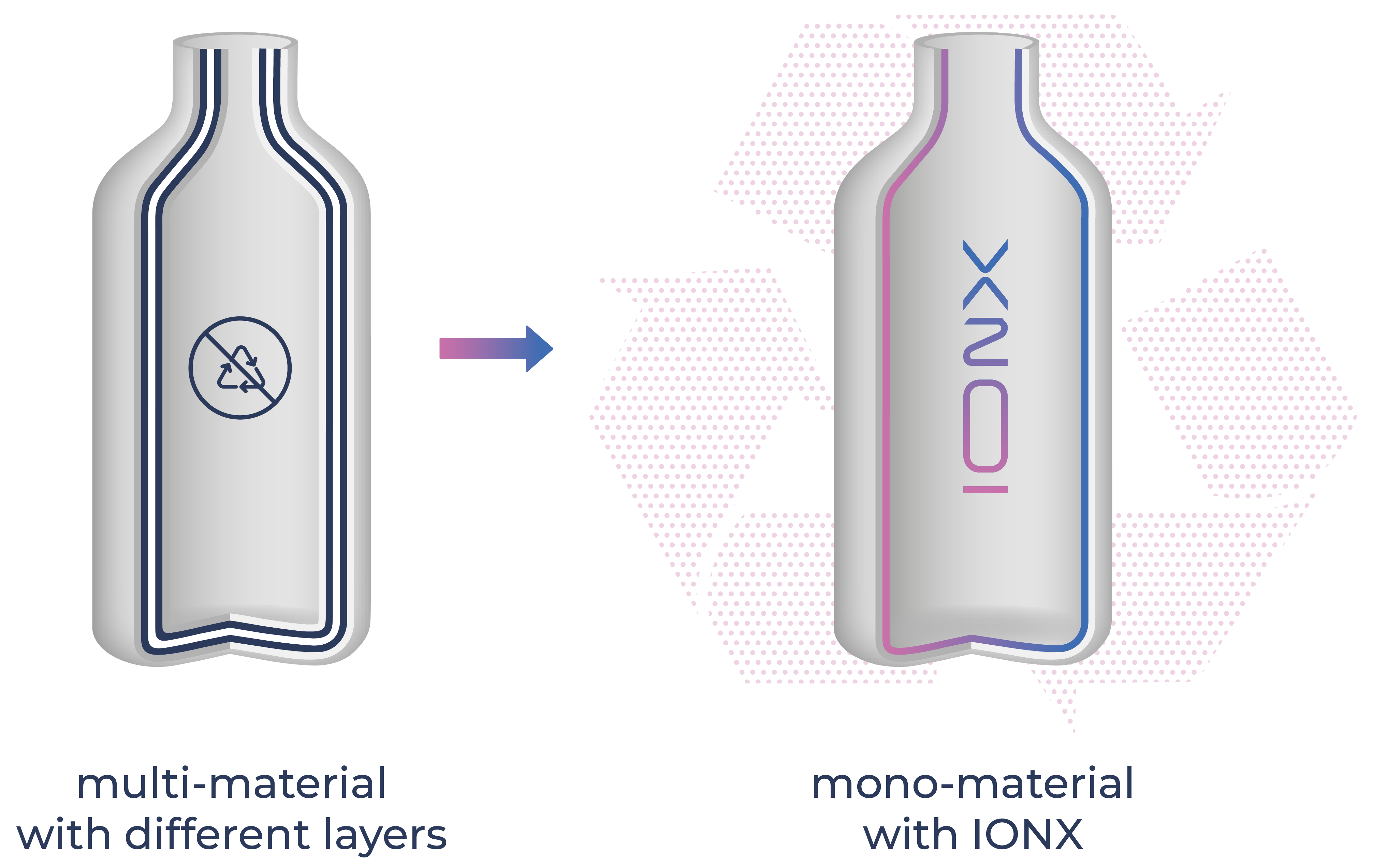

Replace Multi-Layers

Non-recyclable multi-material containers can be replaced with thinly coated mono-materials. The packaging achieves the same barrier properties while being 100% recyclable.

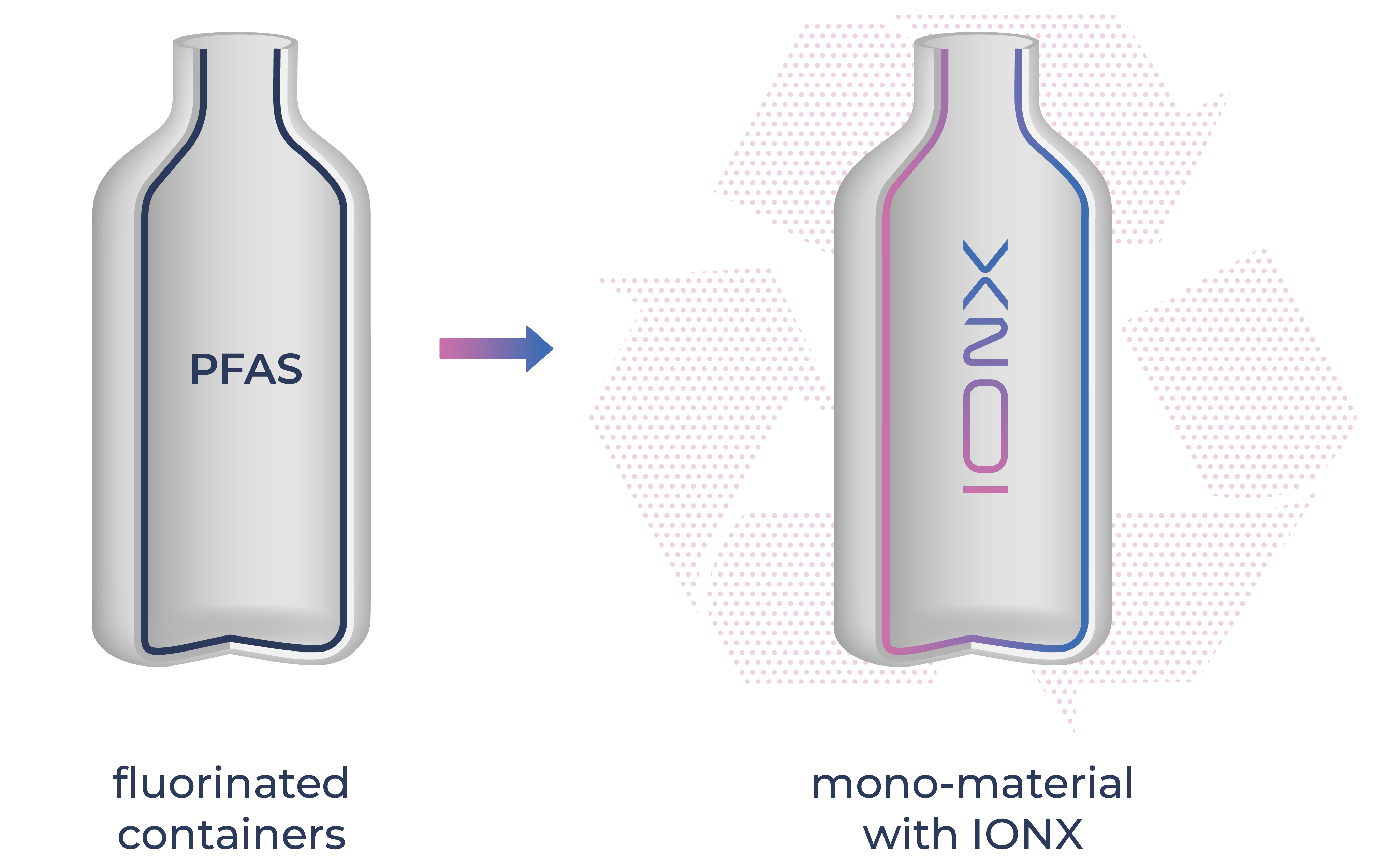

Replace Fluorination

Fluorination is used to create barrier properties, but a ban on fluor is imminent. IONX is the best alternative.

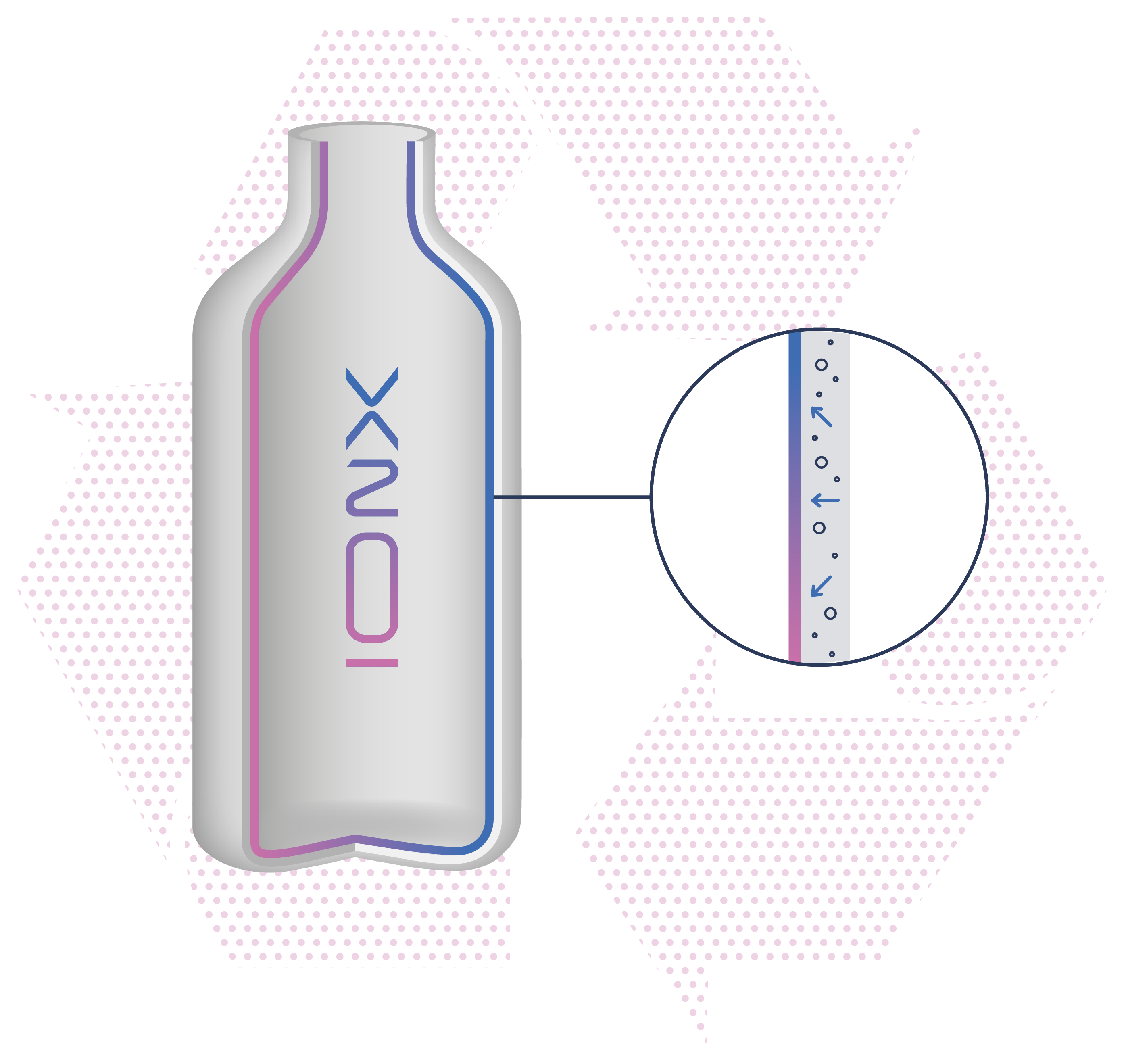

Enable Recyclate

Recyclate cannot be used in packaging for food or cosmetics due to contamination. IONX protects the filled goods, allowing recyclate to be used as the base material.

Proven recyclability of IONX

IONX is chemically bonded to the inner surface of the packaging. It is non-reactive and chemically inert. The coating can be applied to all common packaging plastics like PET or PE-HD. Given that the layer is less than 100 nm thin, the volumetric weight on a standard packaging container is negligible. It, therefore, does not influence the conventional mechanical recycling process of the packaging. Recyclability has been approved by Recyclass, which assess recyclability.